-

-

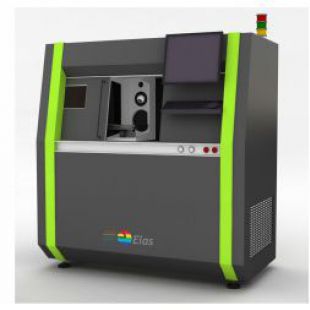

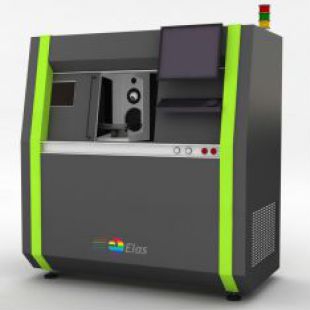

铱拉斯 迷你大师系列

- 品牌:铱拉斯/ELAS

- 型号: Mini MASTER

- 产地:上海 浦东新区

- 供应商报价:面议

-

北京欧兰科技发展有限公司

更新时间:2022-03-04 17:31:39

更新时间:2022-03-04 17:31:39 -

销售范围售全国

入驻年限第10年

营业执照

- 同类产品激光光谱学测试系统(14件)

立即扫码咨询

联系方式:400-822-6768

联系我们时请说明在仪器网(www.yiqi.com)上看到的!

扫 码 分 享 -

为您推荐

详细介绍

Mini MASTER Overview

Mini MASTER workstations are tailored for specific applications. Intended primarily for Research and Development laboratories, Mini MASTERs offer excellent payback while keeping high performance.

Specification

Description

Specifications

Options

Send request

Mini MASTER's are high payback laser micro machining workstations tailored for specific applications in Research and Development laboratories or small batch production.

Being smaller brothers of MASTER workstations, Mini MASTERs perform marking, cutting drilling, surface structuring and fit into reduced foot print.

Ultra short pulse lasers and SCA laser micro machining software complies to high requirements in solar cells applications, extra hard materials processing (like tungsten carbide), etc.

Description

Speed and spatial precision Precision of laser micro machining is achieved by ultra-short laser pulses, state of the art Galvo Scanners and optics. In Mini MASTER workstations nano or pico second laser pulses cause minimal heat-affected zone and maximize spatial precision. High pulse repetition rate and adequate pulse energy ensure fast material removal during ablation or marking. Options of three different working wavelengths offer many machining possibilities for wide range of materials. Accuracy of positioning

Maximum firing accuracy and spatial resolution are achieved due to advanced beam delivery scheme.

Fast galvoscanner for high throughput.

Safety and robustness Class 1 laser-safe and clean-room compatible enclosure ensures robustness and reliability. Advanced control Designed specifically for laser micro machining, SCA software provides automatic control of Mini MASTER workstation, easy design or import of patterns, flexible modification and simulation of micro machining process Applications Ablation Manufacturing of high aspect Micromolds from conductive and non-conductive materials using multiple 2D process

Production of high-aspect ratio micro-

channels fo MicrofluidicsStructuring high density circuit boards for thin films electronics

Cutting and drilling Flexible production of Micromechanics components

Cutting and drilling of saphire and other crystal materials

High-aspect-ratio holes for injectors

Filter production

Marking Surface & intravolume marking of transparent materials

Flexible production of Identification & anti counterfeiting marks

Surface Structuring Clean and accurate modification of wettability characteristics of a wide range of engineering materials

Selective surface structuring for Antireflection

Lubrication modification of 2D and 3D objects

Specifications

Galvo scanner

Scanning field 100 x 100 mm Focal lenght of f-Theta lens 160 mm Marking speed 3,5 m/s Positioning speed 15,0 m/s Laser and motion synchronization Laser pulse synchronized output Optics

Spot size (optics and wavelength dependent) down to 3 μm Output beam single- or multi-wavelength System control Industrial type control computer

LCD display and keyboard

SCA software running on MS Windows OS

Laser and motion synchronization Laser pulse synchronized output Physical Characteristics

Dimensions (approx.), W×D×H 1110×760×1440 mm Power requirements, maximum 2000 W (* Dimensions can be adjusted during design of ordered workstation)

OptionsLaser options

Laser Wawelenght and Power Pulse energy Pulse duration Repetition rate Beam quality Nanosecond laser 20 W @ 1064 nm 8 W @ 532 nm 0.2 mJ @ 1064 nm < 30 ns 5 - 100 kHz M2 < 1.3 Picosecond laser > 16 W @ 1064 nm > 8 W @ 532 nm > 4 W @ 355 nm > 160 μJ @ 1064 nm < 10 ps Single shot to 500 kHz M2 < 1.5 Customization options

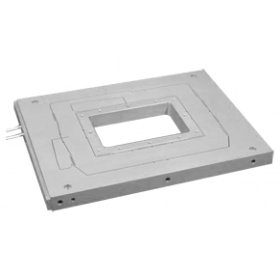

Tables for samples with motorized or manual Z and tilt axis adjustment

Automatic harmonics switching

Automatic focus adjustment

Automatic scanner self - calibration

Vacuum chucks for sample holding

Dust and fume extraction system