Features

| Typical Applications

|

Product Description |

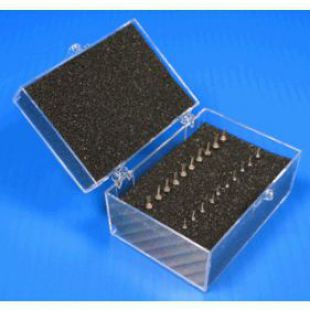

| Mad City Labs offers quartz crystal tuning forks for scanning probe microscopy applications such as atomic force microscopy (AFM) and near-field scanning optical microscopy (NSOM). Each tuning fork has two electrical leads for connection to a driving oscillator such as the Mad City LabsMadPLLinstant AFM and nanoprobe instrumentation. Our tuning forks are shipped to you conveniently ready to use - "out of the can" - with the typical cylindrical housing removed. Available in two sizes: medium and large. Resonant probe AFMs offers several advantages over the optical deflection methods. Laser alignment is not necessary which saves significant time and effort when exchanging probes. The resonant probe only needs basic initial tuning; a process which can be fully automated with commercially available products like theMadPLL. This also translates into a decrease in cost and size of the system because laser and PSD modules are not needed. The use of a deflection laser can also be detrimental to some experiments. NSOM requires low light conditions for optimal signal to noise ratio. The additional light from a laser deflection system can interfere with readings and photobleach samples, hindering the ability to take data. Tuning fork probes are also typically much stiffer and have smaller oscillation amplitudes than cantilever probes. The increased stiffness means that the probe will have higher force sensitivity. The smaller oscillation amplitudes makes it easier to perform various near field experiments as the tip spends most, if not all, of its oscillation cycle near the surface. The tuning forks can also be actuated directly with an electrical signal. This eliminates the need for an external shaker which is necessary for silicon cantilevers working in intermittent or non contact modes. Quartz tuning forks also have extremely stable resonance frequencies, and lower temperature coefficients than silicon, making them less susceptible to drift. Another advantage is that quartz tuning forks are quite plentiful and very inexpensive as they are manufactured by the billions annually for their primary use as time keeping devices. |

Application Example: Tungsten Tip Etching |

An etched tungsten tip glued to a quartz tuning fork. One way to produce sharp probe tips suitable forbuilding an AFMis to electrochemically etch tungsten wire. This method can produce a tip radius of better than 50nm. Post etching techniques can even sharpen the tip down to a <1nm tip radius. These sharp tungsten tips can be mounted to quartz tuning forks for AFM or for other types of scanning probe microscopy like scanning tunne领 microscopy (STM). There are a variety of methods to choose from to etch the tungsten wire. The single lamella technique is easy to setup and can consistently produce sharp tips. Among the requirements for this process are a metallic ring, a beaker, Potassium Hydroxide (KOH), tungsten wire, and a voltage source. A drop of KOH is added to the metal ring suspended above the beaker, forming a thin film or lamella of KOH inside the metallic ring. The negative terminal of the voltage source is then connected to the suspended metallic ring. This will form the negative electrode. The beaker below the ring is then filled with KOH and the positive terminal of the voltage source is wired into the KOH solution. This forms the positive electrode. The tungsten wire is then dipped through the center of the lamella and into the KOH in the beaker. The voltage source is then turned on which begins the etching process. The tungsten is electrochemically etched at the lamella. The etching process automatically stops when the tungsten wire is etched so thin that the portion of wire below the lamella falls off and drops into the beaker. The remaining tungsten wire above the lamella is removed and any remaining KOH or contaminants are rinsed off with distilled water. This leaves a very sharp tip suitable for use in AFM or other types of SPM. See theApplication Note: "Tungsten Tip Etching Station"for further information. |

Electrical Specifications | |

| Center Frequency | 32.768 kHz |

| Oscillation Mode | Fundamental |

| Series Resistance (max.) | 30 kOhm |

| Tolerance (at 25C) | ±18 ppm |

| Operating Temperature Range | -10C to +60C |

| Frequency Stability Over Temperature | -0.038 ppm/C |

| Drive Level | 10μW |

| Shunt Capacitance (max.) | 1.7 pF |

| Motional Capacitance | 2.5 fF |

| Load Capacitance | 12.5 pF |

| Aging (max.) | ±3 ppm/year |

Additional Information | |

Medium Size Tuning Fork Drawing MadPLLBrochure  | Large Size Tuning Fork Drawing AFM Video Tutorial  |

Application Note: "Tungsten Tip Etching Station"  | |

Related Products |

|

上传人:北京欧兰科技发展有限公司

大小:0 B

301

报价:面议

已咨询2134次原子力显微镜(AFM)和近场光学显微镜(NSOM)

报价:面议

已咨询360次激光放大器

报价:¥7

已咨询763次振动式

报价:¥20

已咨询744次振动式

报价:面议

已咨询914次半导体测试设备

报价:¥10

已咨询30次振动式

报价:$38000

已咨询175次弹簧钢拉力试验机

报价:面议

已咨询941次超高真空组件