In order to make the most effective use of your thin film deposition system, it is necessary to understand some of the basic parameters involved in creating thin films. The deposition process can be broadly classified into physical vapor deposition ( PVD ) and chemical vapor deposition ( CVD ). In CVD , the film growth occurs at higher temperatures leading to the development of corrosive gaseous products and might leave impurities on the film. The PVD process can be performed at lower deposition temperatures also leaving corrosive products aside, but deposition rates are lower and it leaves residual compressive stress in the film. Electron beam physical vapor deposition, nevertheless, yields a high deposition rate from 0.1 μm / min to 10 μm / min at relatively low substrate temperatures, with very high material usage efficiency. Due to the very high deposition rate, this process has industrial applications for wear resistant and thermal barrier coatings in aerospace industries, hard coatings for cutting and tool industries, and electronic and optical films for semiconductor industries. In principle, solid evaporant such as powder, granules, lumps, or shaped plug, is placed in the source's copper hearth or in a hearth-liner. A high electron flux produced by hot filament positioned beneath the source is extracted and electro statically and magnetically bent/focused on the top of the evaporant. The electron beam's energy elevates the evaporant's surface temperature. Seldom is the beam rastered to increase the evaporation region. Since the evaporation region is enclosed by cooler (often solid) evaporant, unlike other thermal sources, the e-beam source's vapor plume is chiefly uncontaminated by crucible material. Production scale e-beam sources are usually single pocket (one hearth). Multipocket source (4 or 6 hearths) is available for R & D applications. A cover plate obscures the pockets "not-in-use" to prevent vapor cross talk. Multipocket sources are particularly convenient when depositing multilayer films on a single substrate.

全部评论(0条)

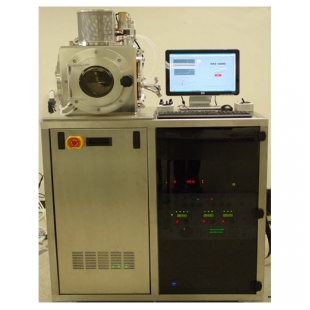

电子束蒸发镀膜机 NEE-4000(A)全自动电子束蒸发系统 那诺-马斯特

电子束蒸发镀膜机 NEE-4000(A)全自动电子束蒸发系统 那诺-马斯特

报价:面议 已咨询 736次

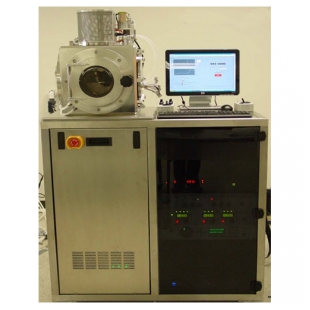

电子束蒸发镀膜机 NEE-4000(M)电子束蒸发系统 那诺-马斯特

电子束蒸发镀膜机 NEE-4000(M)电子束蒸发系统 那诺-马斯特

报价:面议 已咨询 526次

光学镀膜 NOC-4000进口光学镀膜机 那诺-马斯特

光学镀膜 NOC-4000进口光学镀膜机 那诺-马斯特

报价:面议 已咨询 382次

蒸发镀膜设备 NTE-3000热蒸发系统 那诺-马斯特

蒸发镀膜设备 NTE-3000热蒸发系统 那诺-马斯特

报价:面议 已咨询 465次

蒸发镀膜机 NTE-3500(M)热蒸发系统 那诺-马斯特

蒸发镀膜机 NTE-3500(M)热蒸发系统 那诺-马斯特

报价:面议 已咨询 464次

蒸发镀膜设备 NTE-3500(A)全自动热蒸发系统 那诺-马斯特

蒸发镀膜设备 NTE-3500(A)全自动热蒸发系统 那诺-马斯特

报价:面议 已咨询 632次

蒸发镀膜机 NTE-4000(M)热蒸发系统 那诺-马斯特

蒸发镀膜机 NTE-4000(M)热蒸发系统 那诺-马斯特

报价:面议 已咨询 382次

蒸发镀膜设备 NTE-4000(A)全自动热蒸发系统 那诺-马斯特

蒸发镀膜设备 NTE-4000(A)全自动热蒸发系统 那诺-马斯特

报价:面议 已咨询 356次

Syskey 高真空热蒸发镀膜机HV Thermal特点

Syskey 高真空热蒸发镀膜机HV Thermal特点

2025-12-12

Syskey 超高真空热蒸发镀膜机UHV Thermal特点

Syskey 超高真空热蒸发镀膜机UHV Thermal特点

2025-12-12

2023-09-28

2021-10-29

2021-12-06

2025-06-13

①本文由仪器网入驻的作者或注册的会员撰写并发布,观点仅代表作者本人,不代表仪器网立场。若内容侵犯到您的合法权益,请及时告诉,我们立即通知作者,并马上删除。

②凡本网注明"来源:仪器网"的所有作品,版权均属于仪器网,转载时须经本网同意,并请注明仪器网(www.yiqi.com)。

③本网转载并注明来源的作品,目的在于传递更多信息,并不代表本网赞同其观点或证实其内容的真实性,不承担此类作品侵权行为的直接责任及连带责任。其他媒体、网站或个人从本网转载时,必须保留本网注明的作品来源,并自负版权等法律责任。

④若本站内容侵犯到您的合法权益,请及时告诉,我们马上修改或删除。邮箱:hezou_yiqi

参与评论

登录后参与评论